[ad_1]

Citing a latest deadly accident of a Cessna 182 in California, the Nationwide Transportation Security Board (NTSB) has renewed efforts to get the FAA to challenge an Airworthiness Directive for sure oil-filter adapters for Continental engines. The adapters are made by Stratus Software Applied sciences (a part of the Tempest Aero Group) however are sometimes referred to by their authentic designer and producer, F&M Enterprises. Some 11 accidents over the past 15 years have been linked to this filter adapter vibrating free and permitting a lack of engine oil. Stratus has printed a Obligatory Service Bulletin addressing the problem, however FAR Half 91 operators will not be required to adjust to this steering.

The NTSB says the security suggestion “is derived from each preliminary findings of ongoing investigations and our evaluation of investigations and experiences of airplane accidents by which the airplane was geared up with an oil filter adapter meeting put in underneath a supplemental kind certificates (STC). In every of those accidents, oil leaked from the meeting, leading to oil hunger to the engine and a subsequent complete lack of engine energy.”

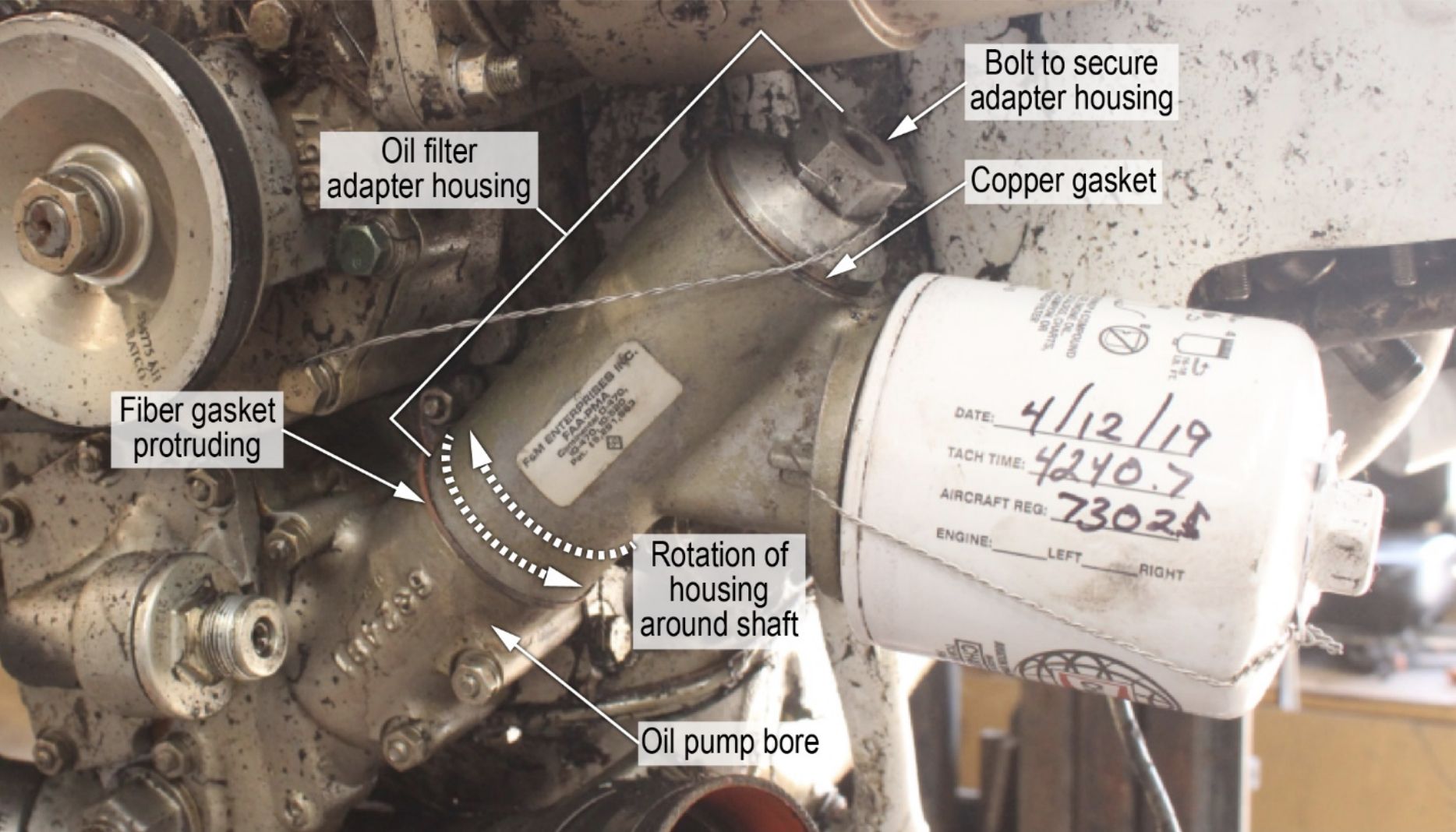

The Stratus adapters are designed to suit a variety of Continental engines, from the small six-cylinder fashions (C-145 and O-300), sure of the bigger IO and TSIO-360 engines, and a large swath of the big-bore O-470, IO-520, TSIO-520, and IO-550 engines. These comparatively early Continental engines have been designed with a easy brass display as a substitute of a paper-element canister oil filter, and the adapter permits set up of a full-flow filter. The adapters screw into the house initially occupied by the brass display. “Two gaskets have been used within the oil filter adapter meeting package: a fiber gasket situated between the oil pump bore and the oil filter adapter and a copper crush gasket situated between the oil filter adapter and the bolt used to safe the adapter housing to the oil pump bore,” in accordance with the NTSB. “The fiber gasket’s function was to create a seal between the oil pump and oil filter adapter, and the copper gasket’s function was to create a seal on the prime of the oil filter adapter housing.”

At challenge is the probability that the filter adapter loosened and dumped the engine’s oil overboard. The NTSB notes that the producers have modified upkeep steering over time. “In Might 2011, F&M [the original STC holder] modified the set up directions to specify that the oil filter adapter should be put in utilizing new gaskets,” says the NTSB. “In October 2013, F&M added a brand new part on gaskets to its ICA that directed the set up of latest gaskets anytime the oil filter adapter is eliminated and re-installed, and the alternative of gaskets at 300 hours or 3 years whichever happens first. More moderen set up directions have eliminated that requirement and as a substitute specify, ‘There aren’t any obligatory alternative occasions for any parts.’”

The NTSB desires the FAA to behave. “Though a SAFO [Safety Alert for Operators] that directs operators to examine, appropriately set up, and preserve oil filter adapters would offer this essential info to operators of airplanes with these oil filter adapters, compliance with a SAFO will not be required. The NTSB due to this fact determines that as a result of house owners who function airplanes underneath Half 91 will not be required to adjust to an SB or SAFO, Stratus’ SB-001 and the FAA’s proposed SAFO could also be inadequate to deal with all affected airplanes, which may end in a gasket rupture, oil hunger, and a subsequent engine failure.”

[ad_2]

Supply hyperlink